Bulb and capillary thermostats in convection ovens provide direct, mechanical control over air temperature inside the heating chamber. Installed in the oven cavity, these thermostats sense thermal changes and actuate switching mechanisms to regulate or limit heat.

For more information or to request a quote, contact us to specify a control or high-limit thermostat for your convection oven system.

Operating Principles of Bulb and Capillary Thermostats in Convection Ovens

Operating Principles of Bulb and Capillary Thermostats in Convection Ovens

Each thermostat consists of a sealed sensing bulb, a fluid-filled capillary tube, and a mechanical switch. When air temperature inside the oven rises, the liquid in the bulb expands, pressurizing the capillary and actuating the switch. This process either opens or closes the electrical circuit, depending on the setpoint and control function.

Thermostats using this design require no external power to operate. The mechanical nature of the system ensures reliability in high-heat environments and eliminates the risk of electronic failure due to temperature cycling.

Control Function for Air Temperature Regulation

Bulb and capillary thermostats in convection ovens serve as primary temperature controllers. Manufacturers place the sensing bulb directly in the oven’s airflow path, enabling rapid thermal response. The switch maintains a target temperature range by cycling the heating element on or off based on a narrow differential.

This mechanical cycling preserves uniform temperature distribution, which is required for cooking accuracy and repeatability in commercial foodservice equipment.

High-Limit Function for Overtemperature Safety

When configured as a high-limit switch, the thermostat interrupts power to the heating elements if air temperature exceeds the maximum threshold. This prevents thermal damage to internal components and ensures compliance with safety regulations.

High-limit models feature fixed setpoints and a manual reset button, providing added protection in the event of airflow blockage or thermostat drift.

Design Parameters for Convection Oven Applications

Engineers select thermostat components based on operating range, bulb length, capillary diameter, and switch configuration. Key parameters include:

-

Bulb placement: Clamped inside the oven cavity for direct sensing

-

Capillary length: Typically ranges from 24″ to 72″ depending on oven size

-

Electrical rating: Designed for resistive loads in 120V, 240V, or 480V systems

-

Setpoint tolerance: Tight calibration tolerances support precise thermal cycling

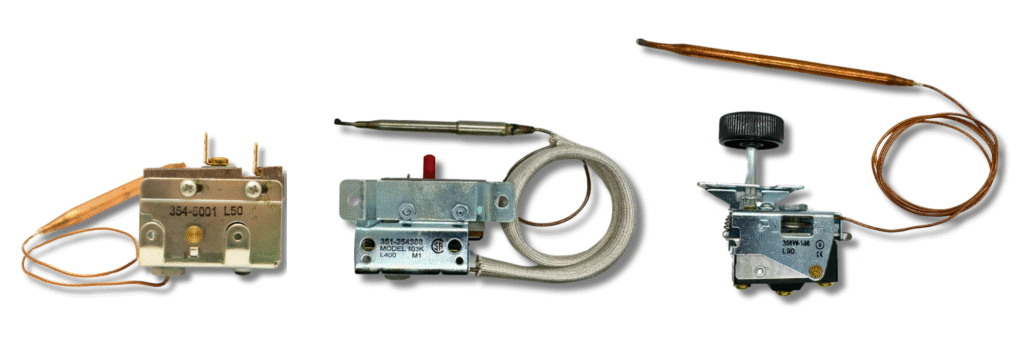

At Stemco, we supply both single-stage and two-stage bulb and capillary thermostats for convection ovens, designed for accurate control and high-temperature durability.

Single-Stage Options

-

351 Series: Flexible design with bulb or probe styles, fixed or adjustable setpoints, and auto or manual reset.

-

354 Series: Tight calibration, through-shaft adjustment, and side mounting for constrained spaces.

-

358 Series: Compact footprint with rear terminals and narrow differential for precise regulation.

All single-stage models use SPDT switch action, with temperature ranges from 0°F to 700°F and a variety of mounting and material options.

Two-Stage – Type 352 Series

The 352 Series uses two separate switches for two-stage or double-pole switch action. These switches can be configured in any combination of SPDT automatic reset switches and/or two SPST manual reset switches.

Supports wide or narrow differentials and is ideal for multistage control or combined control and safety functionality. Rated for 15–25 amps and up to 250°F ambient.

Performance in High-Demand Environments

Manufacturers use bulb and capillary thermostats in convection ovens that operate under constant thermal cycling, grease exposure, and high humidity. Common use cases include:

-

Commercial cooking equipment

-

Bakery and pizza ovens

-

Institutional kitchen ovens

-

Laboratory drying and curing chambers

These thermostats withstand repeated heating cycles without performance drift, supporting long service life with minimal recalibration.

Bulb and capillary thermostats provide straightforward, mechanical temperature control for convection ovens used in the foodservice industry. With single-stage and two-stage models available, they support consistent heat regulation and system protection during continuous operation. Proper thermostat selection helps maintain equipment performance in high-use commercial kitchens.