Commercial kitchen equipment relies on robust mechanical temperature control solutions that provide both regulation and safety protection. Commercial oven temperature switches using bulb and capillary technology deliver precise temperature control and over‑temperature limits without needing auxiliary power or complex electronics. These components function as primary controls and high‑limit safety devices in commercial, industrial, and foodservice ovens.

How Bulb and Capillary Temperature Switches Work

How Bulb and Capillary Temperature Switches Work

Commercial oven temperature switches include three core components:

- A sealed sensing bulb containing a thermally responsive fluid

- A capillary tube that transmits pressure changes

- A mechanical switch housed in a remote control enclosure

As oven temperature rises at the sensing bulb, the fluid expands. Pressure then moves through the capillary tube to a diaphragm or bellows mechanism in the switch housing. As a result, the internal switch activates. When temperature decreases, the fluid contracts, and the switch resets to its original state.

This arrangement enables engineers to position the sensing bulb inside the oven cavity while placing the switch housing in a cooler, more accessible location. As a result, remote sensing improves measurement accuracy and extends the lifespan of critical control components.

Dual Roles: Control and Safety Functions

Commercial ovens require two distinct temperature functions: temperature regulation and over‑temperature safety limits. Commercial oven temperature switches efficiently support both operations.

Temperature Regulation in Ovens

When used as a thermostat, the switch cycles heating elements on and off to maintain consistent internal air temperature. This control mechanism ensures repeatable cooking performance in various commercial oven types, including convection, baking, and combi-style units.

Operators can adjust the setpoint on the control housing. At the same time, the sensing bulb monitors the temperature near the cooking zone. Thermal changes prompt the switch to engage or disengage the heating circuit and maintain stability.

High‑Limit Protection

When configured as a high‑limit device, commercial oven temperature switches cut power to the heating elements if the oven exceeds a defined threshold. These devices are calibrated to meet specific safety parameters. Additionally, many switches include manual reset mechanisms that prevent automatic restarts. This design ensures that personnel investigate abnormal conditions before reactivation.

Mechanical Thermostats in Commercial Oven Systems

Mechanical Thermostats in Commercial Oven Systems

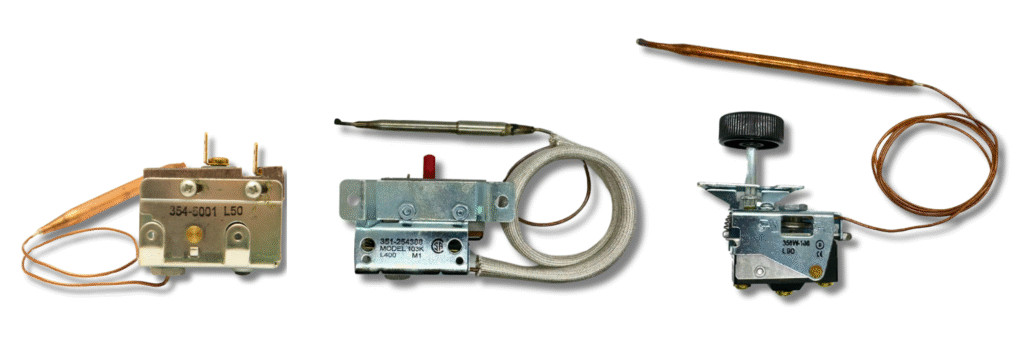

Mechanical thermostats such as the 351, 352, 354, and 358 Series are widely implemented across multiple commercial oven platforms. These devices provide standard temperature control as well as high‑limit protection in demanding environments where convection, humidity, and radiant heat interact. Due to their rugged construction, these switches function reliably even under high moisture and thermal cycling.

Each series offers models with fixed or adjustable setpoints, along with automatic or manual reset options. Consequently, this range enables engineers to specify the right solution for diverse heating system configurations.

Design and Specification Considerations

Bulb Placement & Capillary Length

Proper bulb placement depends on oven construction and thermal dynamics. In standard configurations, bulbs sit in the airflow path. However, in high‑temperature models like pizza or baking ovens, technicians may mount the bulbs to interior wall surfaces for structural temperature sensing. Therefore, capillary lengths typically range from 24″ to 120″ to accommodate flexible routing between sensing and control points.

Electrical Ratings & Setpoints

Commercial oven temperature switches must support system voltages such as 120 V, 240 V, or 480 V and handle resistive loads accordingly. Moreover, accurate calibration ensures the device activates or resets at the intended temperature threshold.

Switch Configurations

To meet varied system needs, manufacturers produce several switch designs:

- Single‑stage switches control or limit heating using SPDT (single‑pole, double‑throw) contacts.

- Two‑stage switches support dual control circuits for combined regulation and safety limit operation.

Typical Food Equipment Applications

Commercial oven temperature switches are commonly installed in:

- Convection ovens

- Baking ovens

- Pizza ovens

- Warming ovens

- Combination ovens

- Rethermalizer ovens

These oven platforms demand mechanical switching systems that endure grease, moisture, and extreme temperature changes. Unlike electronic controls, which often degrade under such conditions, these switches maintain performance.

Advantages of Bulb and Capillary Switch Technology

Commercial oven temperature switches provide multiple system-level benefits:

- Remote sensing enables accurate readings from optimal thermal zones.

- Mechanical actuation eliminates reliance on external power sources.

- Manual reset features add a layer of human oversight during fault recovery.

Bulb and capillary thermostats by Stemco function as commercial oven temperature switches by providing mechanical control and safety shutoff in foodservice and industrial ovens. These devices use fluid expansion in a sensing bulb to actuate a switch remotely, regulating heat or interrupting power at a preset limit. As a proven alternative to electronic systems, bulb and capillary switches offer durability, accuracy, and flexible installation across a wide range of commercial oven designs.