Manufacturers use bulb and capillary switches by Stemco, a division of Senasys, in electric ovens to manage heating cycles and prevent thermal runaway in commercial, industrial, and foodservice equipment. These mechanical controls provide both adjustable temperature regulation and fixed high-limit protection through a remote liquid-filled sensor system. Their versatility, durability, and simplicity make them a reliable solution in oven applications that rely on electrical heating elements to generate high temperatures. To request OEM pricing, contact us. For more information on our 351 series bulb and capillary switches, visit the product page.

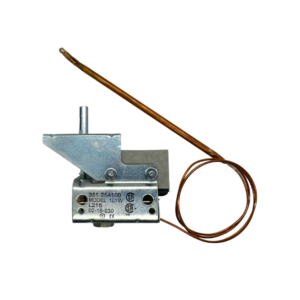

Each switch includes a sealed, liquid-filled sensing bulb connected to a diaphragm head by a capillary tube. As the bulb heats, the liquid expands, which moves the diaphragm and actuates an internal microswitch. The switch opens or closes the circuit depending on system wiring. With the sensing point placed remotely, users can mount the control housing on a panel or enclosure away from the heat source.

Manual Reset High Limit Switches for Oven Safety

Manual Reset High Limit Switches for Oven Safety

Manufacturers install manual reset bulb and capillary switches in electric ovens as high-limit cutoffs to protect against overheating. These switches trip at a fixed temperature setpoint when the system exceeds safe operating conditions due to control failure or airflow loss. After tripping, the switch remains open until an operator resets it manually, ensuring human oversight before the oven resumes operation.

Stemco high-limit switches feature:

- SPST break-on-rise switching

- Fixed temperature setpoints up to 700°F

- Manual reset pushbutton on the housing

- Rugged panel-mount or enclosure-ready housing designs

- Bulbs designed for air immersion or surface mounting inside the oven cavity

Oven manufacturers use these switches in dish machine booster ovens, pizza ovens, and convection ovens to provide a dependable backup against overheating.

Adjustable Control Switches for Oven Temperature Regulation

Manufacturers also rely on adjustable bulb and capillary switches as the primary temperature control for electric ovens. These switches use SPDT switching to cycle heating elements on and off as temperatures rise and fall relative to the setpoint. Operators set the desired temperature using a front-facing dial or screw, while the sensing bulb monitors the target zone within the oven.

Stemco adjustable switches offer:

- SPDT switching for control circuits

- Adjustable temperature ranges up to 700°F

- Panel-mount enclosures with dial or shaft adjustment

- Remote sensing bulbs with capillary lengths up to 120 inches

- CSA and UL recognition for oven equipment

System designers often use both switch types in tandem—one for real-time control and one as a backup limit—to meet safety codes and ensure long-term reliability in high-temperature cooking systems.

Oven Integration and Customization Options

Engineers can integrate Stemco bulb and capillary switches into electric oven assemblies with the following available features:

- Stainless steel, dull nickel plated, or copper bulb and capillary tubes

- Mounting brackets and thermowell compatibility (as needed)

- Vertical or remote diaphragm head mounting

Applications That Use Bulb and Capillary Switches in Electric Ovens

Applications That Use Bulb and Capillary Switches in Electric Ovens

OEMs integrate Stemco switches into a wide variety of electric ovens, including:

- Commercial baking ovens and proofers

- Electric booster ovens in dishwashing stations

- Warming ovens and food holding cabinets

- Rethermalizers and countertop ovens in quick-serve kitchens

- Electric Convection Ovens

- Electric Combi Ovens

- Electric Rethermalizers

By incorporating bulb and capillary switches in electric ovens, manufacturers maintain stable heating control and safeguard against overheating. These mechanical switches function independently of digital systems, making them ideal for applications requiring simplicity, reliability, and operation at high temperatures.