Single stage bulb and capillary switches for proofing cabinets deliver mechanical temperature control and thermal safety in commercial food equipment. These switches operate as control units to maintain proofing conditions or as high limit devices to disconnect power during over-temperature events. Our models are built for OEM integration and are available in a range of configurations to support diverse cabinet designs. For technical specifications, part numbers, or application support, please contact us. Our engineering team can assist with custom configurations to meet your system requirements.

Precision Temperature Control for Dough Proofing Environments

Proofing cabinets are used in bakeries, commercial kitchens, and institutional foodservice operations to create warm, humid environments that support dough fermentation. Stable internal temperature is essential for consistent product quality and process control.

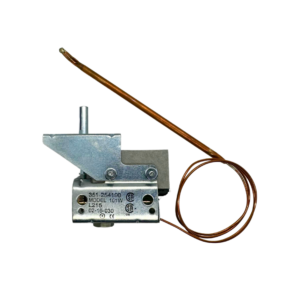

Bulb and capillary switches function as the primary control mechanism in analog proofing cabinets. The sensing bulb monitors cabinet air temperature. Fluid inside the capillary tube expands with heat, actuating a mechanical switch that controls the power to the heating element. This maintains a preset temperature setpoint, typically between 80°F and 100°F, ensuring uniform dough development without overheating or drying.

Integrated High Limit Protection for Equipment Safety

In addition to temperature control, bulb and capillary switches also serve as high limit devices. When used in this role, the switch monitors cabinet temperature and disconnects the heating element if conditions exceed a fixed safety threshold. This prevents overheating, protects internal components, and reduces equipment failure risk. High limit switches are often required for compliance with food equipment safety standards.

Available in manual or automatic reset versions, these switches allow OEMs to specify the appropriate protection strategy for their proofing cabinet designs.

Technical Design Features for OEM Integration

Technical Design Features for OEM Integration

-

Remote Bulb Sensing with Capillary Tubes: Supports accurate temperature monitoring across varied internal cabinet locations.

-

Mechanical Switch Actuation: Operates independently of control boards or power supplies, increasing system durability and simplifying design.

-

Tight Temperature Control Range: Maintains consistent chamber conditions with minimal temperature swing.

-

OEM-Compatible Form Factors: Offered in various capillary lengths, bulb sizes, temperature ranges, and mounting styles to meet integration requirements.

-

Commercial-Grade Materials: Built to perform in humid, high-use foodservice environments.

Engineered for Food Equipment Manufacturers

Stemco supplies bulb and capillary switches engineered to meet the temperature control and safety needs of commercial proofing cabinets. Our components support consistent performance, regulatory compliance, and system longevity.

For detailed product data and OEM support, visit the product pages or contact our technical team.