Bulb and capillary thermostats provide precise temperature control, high-limit safety protection, and remote sensing for electric heaters. These thermostats allow engineers to position the sensing bulb directly in the heated zone while keeping the control mechanism away from high temperatures. Contact our engineering team today to configure a thermostat assembly that meets your temperature range, mounting requirements, and certification needs.

Temperature Control in Electric Heater Applications

Temperature Control in Electric Heater Applications

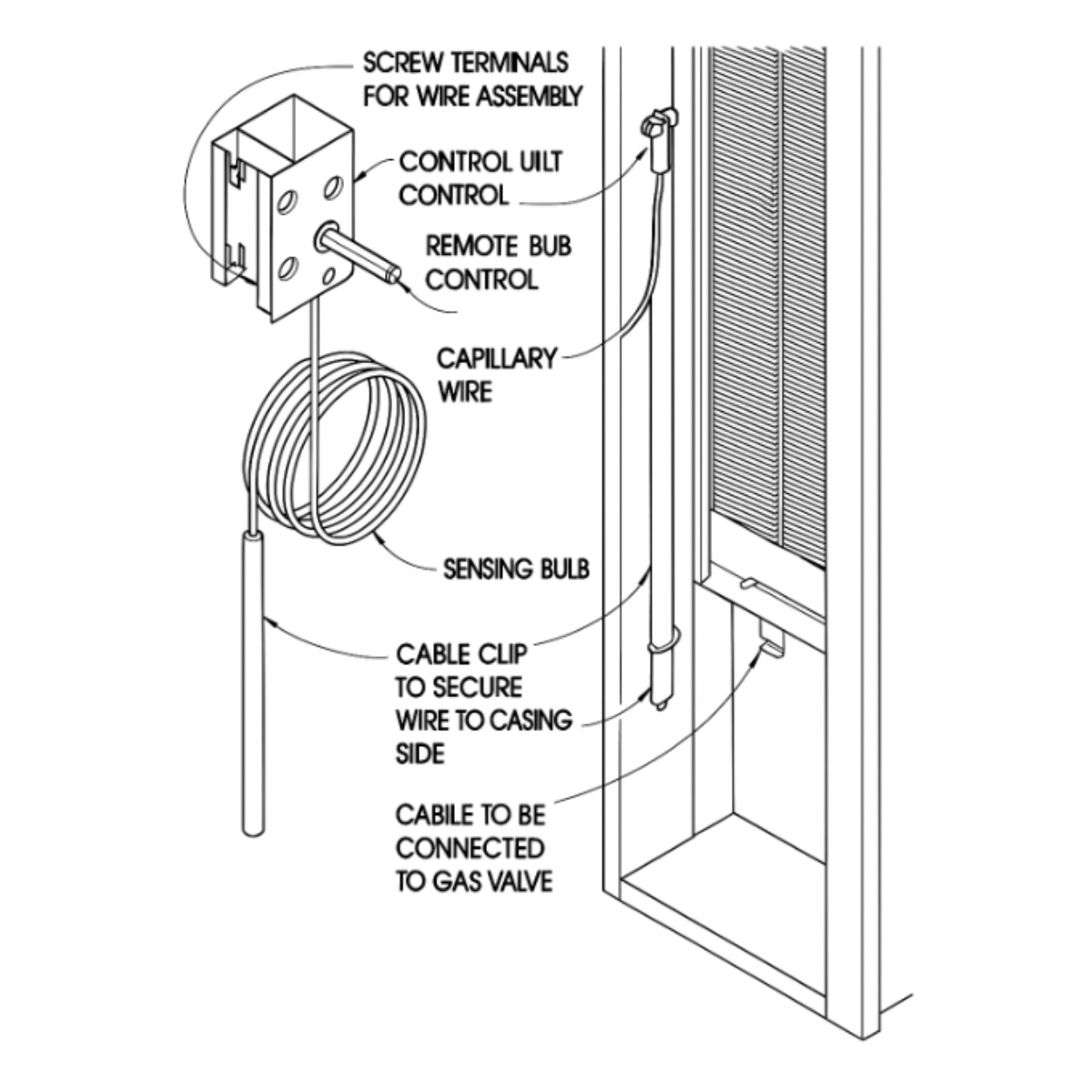

Bulb and capillary thermostats regulate electric heater output by sensing temperature at the bulb and switching power at the defined setpoint. Engineers use these thermostats where the sensing location must be remote from the control device or where temperature conditions exceed the limits of traditional integrated thermostats.

High-Limit Safety Protection

Electric heaters require high-limit protection to prevent overheating and thermal damage. Bulb and capillary thermostats provide this function by interrupting power when the heater temperature exceeds the safety threshold. This method supports compliance with application-specific safety requirements and helps protect equipment and surrounding systems.

Remote Sensing for Flexible Designs

Separating the sensing bulb from the switch body gives engineers flexibility in component placement. The bulb can be installed inside ducts, tanks, or heater enclosures while the switching mechanism remains in a cooler, accessible area. This design simplifies maintenance and supports more efficient heater layouts.

Custom Configuration for OEM Requirements

Standard thermostats often fail to meet the space, mounting, or documentation needs of specific heater designs. Configurable bulb and capillary assemblies address these limitations with selectable temperature ranges, switching differentials, and mounting interfaces. These solutions integrate easily into electric heater systems while meeting required certification standards.

Electric Heater Applications

-

Duct heaters for air handling systems

-

Immersion heaters for water, oil, or chemical solutions

-

Process heaters for manufacturing operations

-

Tank and vessel heaters for fluid temperature control

Key Advantages of Bulb and Capillary Thermostats in Electric Heaters

-

Accurate temperature control at remote sensing points

-

Integrated high-limit protection for safety compliance

-

Flexible mounting options for challenging layouts

-

Full documentation for certification and regulatory support

For additional information on our bulb and capillary thermostats, visit the product page.