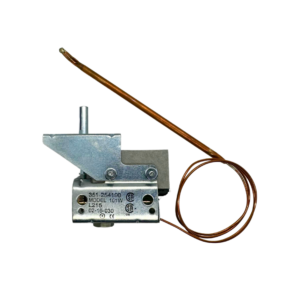

The 351 Series bulb and capillary switches provide accurate temperature control in industrial fluid heaters where maintaining thermal consistency is critical. For engineers and OEMs integrating thermal regulation components, this series offers a mechanical solution that meets rigorous application requirements. Contact us to specify a configuration for your system.

Function of 351 Series Bulb and Capillary Switches in Fluid Heaters

Function of 351 Series Bulb and Capillary Switches in Fluid Heaters

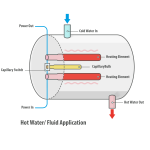

Bulb and capillary switches use a fluid-filled sensing bulb connected to a capillary tube and a diaphragm. When the process fluid reaches a defined temperature, the fluid inside the bulb expands. This expansion creates pressure that travels through the capillary tube, which transmits the force to a diaphragm. The diaphragm actuates a mechanical switch that opens or closes a circuit controlling the heating element.

The capillary enables remote sensing—allowing the bulb to be positioned in the heated fluid zone while the switch is located away from high temperatures or restricted areas. This design is well-suited for industrial fluid heaters where electrical components must remain isolated from heated sections or where equipment layout requires flexible sensor placement.

For more information on our 351 series. visit the product page.

Specifications Supporting Temperature Control

-

Temperature Range: Adjustable across a wide span to meet common thermal requirements in fluid processing systems.

-

Switch Type: SPDT (single-pole, double-throw) switch design for dual-circuit control, supporting both active heating and limit protection.

-

Sensing Bulb Materials: Available in copper, nickel-plated copper, and stainless steel to support various media and corrosion environments.

-

Mounting Options: Panel, side, and back-mount configurations for easy integration into a range of system architectures.

-

Capillary Lengths: Offered in different lengths to optimize remote sensing and switch placement.

Advantages of Using Bulb and Capillary Switches for Industrial Fluid Heaters

Advantages of Using Bulb and Capillary Switches for Industrial Fluid Heaters

Industrial fluid heaters require precise temperature regulation to prevent overheating, fluid degradation, or inconsistency in thermal transfer. The 351 Series activates the heating element when the fluid temperature drops below the setpoint and deactivates it once the desired temperature is restored. This cycle maintains a uniform fluid temperature and helps protect the system from thermal stress.

The mechanical nature of bulb and capillary switches means no external power is required for the sensing or switching function, reducing complexity and increasing reliability. Their remote sensing capability also supports safe and effective layout planning in equipment design.

Application Fit

Bulb and capillary switches for industrial fluid heaters are commonly used in closed-loop heating systems, laboratory recirculators, thermal fluid reservoirs, and other environments where maintaining steady process temperatures is essential. These applications benefit from accurate mechanical switching and the ability to locate sensing and control components independently.

The 351 Series bulb and capillary switches are engineered for consistent temperature regulation in process heating systems. With remote sensing capability, a mechanical actuation mechanism, and flexible configuration options, they offer a reliable solution for fluid heating applications. Contact us to select the right model for your system requirements.