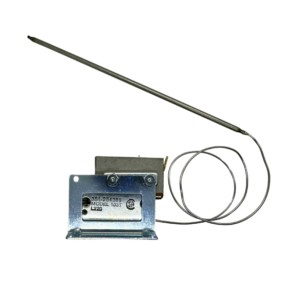

In industrial temperature regulation, bulb and capillary thermostats play a crucial role in controlling heating elements with precision. We specialize in manufacturing these thermostat units, which consist of three key components: the sensing bulb, the capillary, and the microswitch. These units integrate into temperature controllers to ensure accurate thermal management in various industrial systems.

Our thermostat units have earned a reputation for durability and precision engineering. Designed to meet the demanding needs of industrial environments, they provide long-term reliability and consistent performance. If you’re looking for high-performance components to enhance your temperature control systems, we offer custom configurations to meet your specific requirements.

For more information or to request OEM pricing, contact us today and learn how we can support your manufacturing needs.

The Functionality of Bulb and Capillary Thermostats

Bulb and capillary thermostats operate by detecting changes in temperature through the sensing bulb, which is immersed in the medium being monitored. The capillary transmits this thermal data to the microswitch, which then activates or deactivates the heating element. The thermostat’s precise performance directly impacts the reliability of the temperature controller it’s used in.

Bulb and capillary thermostats operate by detecting changes in temperature through the sensing bulb, which is immersed in the medium being monitored. The capillary transmits this thermal data to the microswitch, which then activates or deactivates the heating element. The thermostat’s precise performance directly impacts the reliability of the temperature controller it’s used in.

The Bulb: Acts as the primary temperature sensor, immersed in the target environment. It responds to thermal changes, causing pressure fluctuations in the system.

The Capillary: Transfers pressure changes from the bulb to the microswitch, ensuring the control mechanism receives accurate data.

The Microswitch: Reacts to pressure transmitted by the capillary, controlling the operation of the heating element. It either maintains an adjustable temperature or functions as a high-limit control, shutting down the system when maximum temperatures are exceeded.

Importance of Our Bulb and Capillary Thermostat Units in Temperature Controllers

At Stemco, we supply complete bulb and capillary thermostat units to manufacturers, helping them produce high-performance temperature controllers for a wide range of industrial applications. Our thermostats offer several critical advantages:

At Stemco, we supply complete bulb and capillary thermostat units to manufacturers, helping them produce high-performance temperature controllers for a wide range of industrial applications. Our thermostats offer several critical advantages:

Accurate Temperature Control: The combination of a high-quality sensing bulb, responsive capillary, and reliable microswitch allows for smooth on-off cycling of heaters, preventing temperature overshoot or undershoot.

High-Limit Safety: Many industries rely on our thermostats to protect equipment. The microswitch ensures that power to the system is cut once temperatures reach the pre-set limit, preventing overheating and damage.

Durable Construction: Built to endure extreme conditions, our thermostats function reliably under high temperatures, pressure, and harsh environments.

Technical Specifications and Features

We design our thermostats for versatility and reliability, offering key technical advantages:

Custom Configurations: We provide various bulb sizes, capillary lengths, and microswitch ratings to meet the specific needs of each application.

Precision Manufacturing: Our thermostats are engineered to strict tolerances, ensuring accurate temperature sensing and quick response times. This is especially important in environments where temperature fluctuations can affect operational efficiency or product quality.

Long-Term Durability: Our units are built to last, operating in extreme conditions without degradation. The robust construction ensures reliable performance, even under continuous use.

Applications

Our bulb and capillary thermostats integrate into temperature controllers across various industries, offering dependable performance:

HVAC Systems: Our units help regulate air temperature, ensuring consistent heating and cooling without overheating.

Industrial Ovens and Furnaces: The precise control and high-limit safety features ensure stable temperatures in high-heat environments.

Refrigeration Systems: Our thermostats maintain specific temperature ranges in cooling systems, protecting perishable goods from spoilage or damage.

Process Heating Systems: In industries like food processing, chemical production, and material handling, maintaining strict temperature control is critical to ensuring product quality and operational efficiency.

Why Manufacturers Choose Our Thermostat Units

Manufacturers prefer our bulb and capillary thermostats for several reasons:

Consistent Accuracy: Our components provide fast, accurate feedback, ensuring that temperature controllers respond quickly to changing conditions.

High-Performance Materials: Each unit is constructed using materials designed to withstand extreme temperatures, mechanical stress, and environmental challenges. This ensures reliable operation, even in demanding industrial environments.

Custom Solutions: We offer flexibility in design, allowing manufacturers to select the optimal bulb size, capillary length, and microswitch configuration for their specific needs. This enables easy integration into various types of temperature controllers.

As a trusted supplier, we provide manufacturers with high-performance thermostat units that serve as the backbone of reliable temperature controllers. Our precision-engineered components ensure accurate thermal management, fast response times, and long-term durability across a broad range of industrial applications. Partner with us to produce temperature controllers that deliver consistent, safe, and efficient operation.