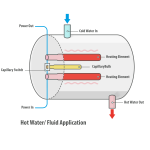

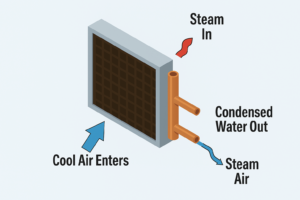

Steam coils are used across industrial air handling units, process heating systems, and HVAC equipment. They transfer heat from steam into airflow or process streams. For safe operation, airflow must remain consistent and steam flow must be tightly controlled. If air ducts become blocked, a steam valve sticks open, or a control system fails, steam coil overheating can occur — potentially damaging equipment and creating unsafe conditions.

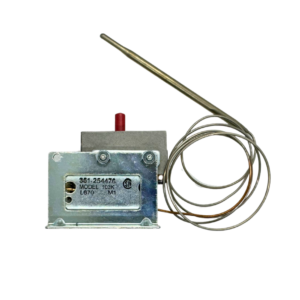

A manual reset capillary thermostat by Stemco, a division of Senasys, is one of the simplest and most reliable ways to provide steam coil overtemperature protection. Installed directly at the coil or in the surrounding duct, the thermostat monitors temperature and shuts down steam flow if temperatures exceed a safe limit. With a manual reset, the thermostat ensures operators investigate and correct the problem before restarting the system.

To learn more about manual reset capillary thermostats or to find the right product for your steam coil overtemperature protection needs, visit the product page or contact our team.

How a Manual Reset Capillary Thermostat Provides Steam Coil Overtemperature Protection

A capillary thermostat consists of a sensing bulb, a capillary tube, and a switch mechanism.

The sensing bulb is placed inside the coil or duct, where it monitors either air temperature or steam temperature. The bulb contains a liquid that expands as temperature increases, transmitting pressure through the capillary tube to the thermostat body.

If the temperature exceeds the thermostat’s preset limit, the thermostat’s internal switch opens, cutting power to the steam valve or triggering a system shutdown.

With a manual reset design, the system stays shut down until an operator physically resets the thermostat at the panel or local reset point. This feature is critical for reliable steam coil overtemperature protection because it ensures the overheating event is reviewed and addressed before the system is returned to service.

Common Causes of Overtemperature in Steam Coils

A manual reset capillary thermostat protects steam coils from a range of potential failure conditions, including:

Blocked airflow — When ducts become blocked or fans fail, airflow across the steam coil is reduced or eliminated. Without airflow to remove heat, the coil temperature rises quickly.

Stuck open steam valves — If a steam valve fails in the open position, steam continues flowing through the coil even if the system is not calling for heat.

Control system failures — If the primary temperature controller malfunctions or loses power, steam could continue flowing uncontrolled.

In each of these cases, steam coil overtemperature protection depends on an independent safeguard like a manual reset capillary thermostat to prevent runaway temperatures.

Why Manual Reset is Critical for Steam Coil Safety

Why Manual Reset is Critical for Steam Coil Safety

Automatic reset devices may allow equipment to restart without operator awareness — leaving the root cause of an overtemperature event unresolved. A manual reset thermostat, on the other hand, locks the system out until:

- A technician inspects the system

- The cause of the overtemperature condition is found and corrected

- The thermostat is manually reset by authorized personnel

This manual intervention process is a key part of effective steam coil overtemperature protection, especially in applications where overheating could damage equipment, disrupt processes, or pose safety risks.

Advantages of Capillary Thermostats for Steam Coil Overtemperature Protection

Mechanical operation — Capillary thermostats operate using fluid expansion inside the sensing bulb, meaning they function independently of the primary control system and do not require power for sensing or tripping. This adds a reliable backup layer to the system.

Remote sensing installation — The sensing bulb is installed directly at the coil or duct, but the thermostat body (where the manual reset is located) can be placed in a convenient location for access. This simplifies both installation and ongoing maintenance.

Adjustable or fixed setpoints — Thermostats can be ordered with either fixed overtemperature limits or field-adjustable limits to match specific process requirements.

Reliable trip and lockout — Once the thermostat trips due to high temperature, it locks out further operation until the issue is fully investigated and the thermostat is manually reset. This lockout process is essential for effective steam coil overtemperature protection.

Where Steam Coil Overtemperature Protection is Needed

Manual reset capillary thermostats are used for steam coil overtemperature protection in:

- Air handling units with steam heating coils

- Industrial ovens and dryers using steam coils

- Process air heaters in manufacturing

- HVAC systems for commercial and industrial buildings

- Any system where overheating could cause equipment damage or safety risks

A capillary thermostat is one of the most reliable tools for steam coil overtemperature protection. By sensing coil or air temperature directly and shutting down steam flow when temperatures exceed safe limits, these thermostats help protect equipment, maintain safe operation, and prevent costly failures. The manual reset requirement ensures that every overtemperature trip is investigated before the system returns to service, adding an essential layer of operational oversight.