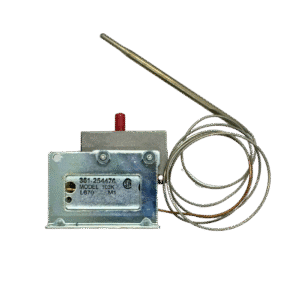

Stemco’s 351 Series functions as a mechanical thermostat for combi ovens, used to regulate temperature or to interrupt power during overtemperature conditions. It operates without electronics and withstands steam, heat, and high-duty cycles. With multiple control and safety configurations, the 351 Series suits OEM designs and field service requirements in commercial kitchen systems. To request OEM pricing, contact us. For more information on our 351 series bulb and capillary switches, visit the product page.

What Is a Combi Oven?

A combi oven uses convection, steam, or both to cook food with consistent heat distribution and moisture control. These units support faster cooking times, better texture, and reduced shrinkage in food service environments. Because combi ovens combine two heat sources, they require tight thermal management to avoid overheating, material degradation, or safety shutoff events.

Mechanical Thermostat Use in Combi Ovens

Temperature Control

In this mode, the 351 Series monitors the oven or steam generator temperature using a sealed fluid-filled sensing bulb and capillary. As the fluid expands with rising temperature, it actuates an internal switch to cycle the heater on or off. The switch responds directly to thermal input, with no software, relays, or sensors involved. Users or installers set the desired control point with a screw adjustment at the time of commissioning or during maintenance.

High-Limit Protection

As a high-limit cutoff, the thermostat disconnects power to the heating element if the oven exceeds a fixed maximum temperature. This serves as a backup in case of airflow blockage, control failure, or extended overheating. Manual reset versions require physical reset before restoring power, which ensures that staff addresses the cause of the trip before resuming operation. Units are either factory-fixed or configured with tamper-resistant adjustment features depending on the application.

Mechanical Design Advantages

Operates in Harsh Conditions

The 351 Series handles conditions found in combi ovens, including continuous steam exposure, temperature spikes, and fluctuating electrical supply. Its mechanical switching action is unaffected by condensation, sensor drift, or EMI, making it a solid choice where digital systems struggle to maintain reliability.

Fast Service and Setup

Maintenance staff can replace the thermostat using standard tools. No calibration software or diagnostic equipment is needed. Adjustable models include an external setpoint dial, allowing on-site tuning based on system requirements or performance feedback. Field replacement takes minutes and requires minimal disassembly.

Small Footprint, Flexible Layouts

The compact housing allows installation in tight compartments, whether within the oven cavity, control box, or near heating components. Capillary tubes are available in various lengths to reach remote locations while keeping the switch body protected. Bulb options include straight, coiled, or flange-mounted types to match thermal contact requirements.

Typical Mounting Locations

Typical Mounting Locations

-

Steam generator housings: Used to control or limit the temperature of steam-generating components

-

Heating element brackets: Monitors surface or air temperature near resistive or induction heating zones

-

Airflow and recirculation paths: Ensures heated air remains within specified limits for convection cycles

-

Oven cavity walls: Provides cavity temperature feedback in contact or proximity positions

-

Control panels or safety enclosures: Used for integrated limit circuits outside the heated zones

Configuration Options

-

Single-stage adjustable control: Provides on/off switching at a field-set temperature for active regulation

-

Manual reset high-limit only: Opens at a fixed temperature and requires reset to resume operation

-

Dual-switch (adjustable + manual reset): Combines both control and safety cutoff in one compact assembly

-

Bulb and capillary variations: Multiple lengths, profiles, and mounting methods available for fit and thermal response

-

Wide temperature range options: Supports low and high temperature setpoints for diverse oven models

Installed Across Commercial Oven Platforms

Manufacturers and service technicians use the 351 Series mechanical thermostat by Stemco, a division of Senasys, for combi ovens to control thermal cycling and enforce safe operating limits. The mechanical build and direct actuation provide repeatable performance across thousands of heating cycles. Its design supports both OEM installation and field retrofit in new or legacy systems.

To select the right configuration or request technical support, contact us. We supply mechanical thermostats built for the operating conditions found in commercial cooking equipment.