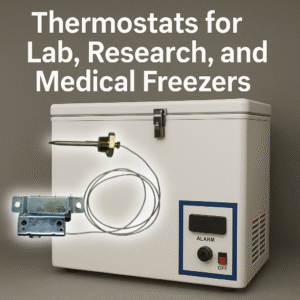

Low temperature freezers play a critical role in laboratory, research, and medical environments. These units preserve materials that must remain stable under precise thermal conditions, including vaccines, biological specimens, enzymes, reagents, and specialty pharmaceuticals. Even a brief temperature deviation can result in irreversible damage or failed storage. Reliable thermal control is non-negotiable.

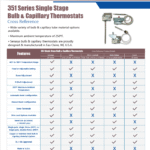

The 351 Series Capillary Thermostats provide mechanical temperature regulation for these high-demand applications. It functions as either a fixed or adjustable control and integrates easily with the cooling systems used in low temperature freezers. The 351 Series offers accurate, repeatable switching without introducing complexity or the maintenance burden of digital controllers.

View more info on our 351 series or contact us for OEM pricing and custom options

Thermostat Function in Low Temperature Freezer Systems

Thermostat Function in Low Temperature Freezer Systems

Lab and medical freezers often rely on cold wall refrigeration and gravity air circulation. These systems require consistent temperature control to protect contents during long-term storage. The thermostat monitors cabinet conditions and controls when the compressor starts or stops, maintaining steady thermal balance.

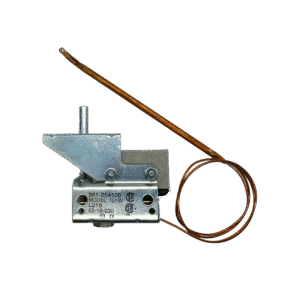

The 351 Series uses a fluid-filled sensing element that responds to changes in ambient or surface temperature. As the sensor detects changes, it actuates a mechanical switch that completes or interrupts the circuit. This action provides direct control over the refrigeration cycle. Fixed temperature models are commonly used as high or low limits to prevent thermal excursions. Adjustable models give operators flexibility to match the thermostat’s set point to specific storage needs.

Temperature Control Built for Medical, Research and Laboratory Environments

Conditions in laboratory and clinical freezers are demanding. Equipment must operate for extended periods, withstand frequent access, and perform in environments where humidity and condensation can degrade electronic components. The 351 Series Capillary Thermostats are ideal for these settings because it requires no software, no calibration, and no external power to function.

Unlike digital boards that can drift or fail due to voltage issues, the 351 Series offers mechanical dependability. It performs consistently in facilities that cannot risk failure or unplanned downtime.

Custom Fit for OEMs and Retrofits

Custom Fit for OEMs and Retrofits

The 351 Series is engineered for integration into new freezer designs or direct replacement in existing systems. Available in multiple mounting formats with either bulb and capillary or probe-style sensors, it installs without major rework. It covers a wide temperature range from -40°F to 700°F and can be configured with manual or automatic reset, screw-driver or D-shaft adjustment, and in copper, plated copper, or stainless steel builds. This range of options allows OEMs and service technicians to match the thermostat to specific mechanical or environmental conditions.