Prevent accidental discharge and improve equipment safety with our Temperature-Actuated Fluid Drain Valve Lockout. This mechanical lockout device restricts valve operation when liquid or vapor temperatures exceed 125°F, minimizing the risk of operator exposure to high-temperature fluids. The product is currently in development. Contact us to discuss OEM integration opportunities.

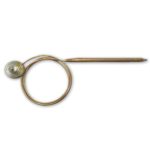

Hydrastat Temperature Sensing for Reliable Actuation

This system uses the 368 Hydrastat capillary tube sensor to provide precise temperature monitoring and mechanical actuation. The 368 is engineered to sense temperatures from -40°F to 700°F. It offers maximum diaphragm travel between 0.028″ and 0.045″, depending on cup size. Available in copper, nickel-plated copper, or stainless steel, the sensor supports capillary diameters of 0.059″ or 0.078″ and cup sizes of 5/8″, 3/4″, 1″, or 1.5″.

Bulb dimensions and cup size must be selected based on the desired movement at the target temperature. This ensures accurate and consistent actuation in thermally controlled mechanical systems. Learn more about the 368 Hydrastat temperature sensor and its integration options.

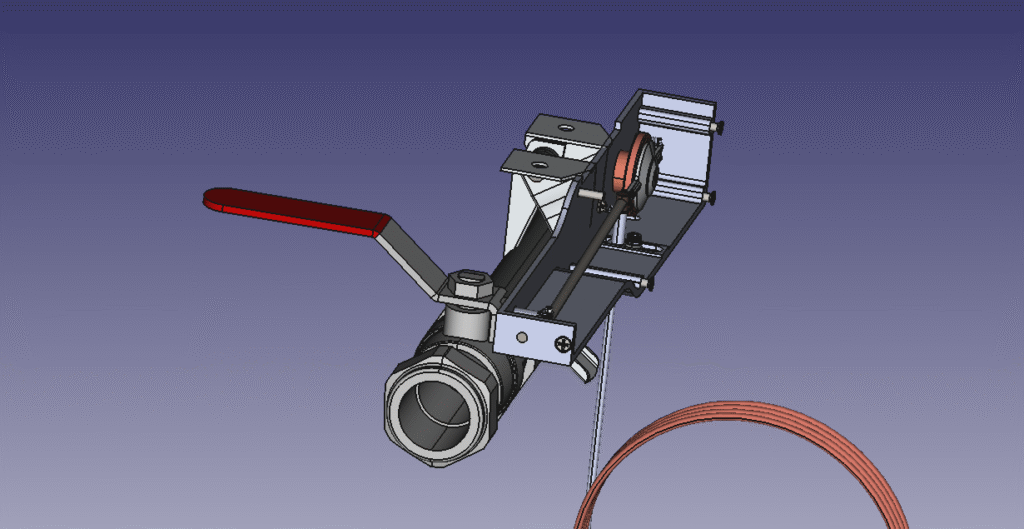

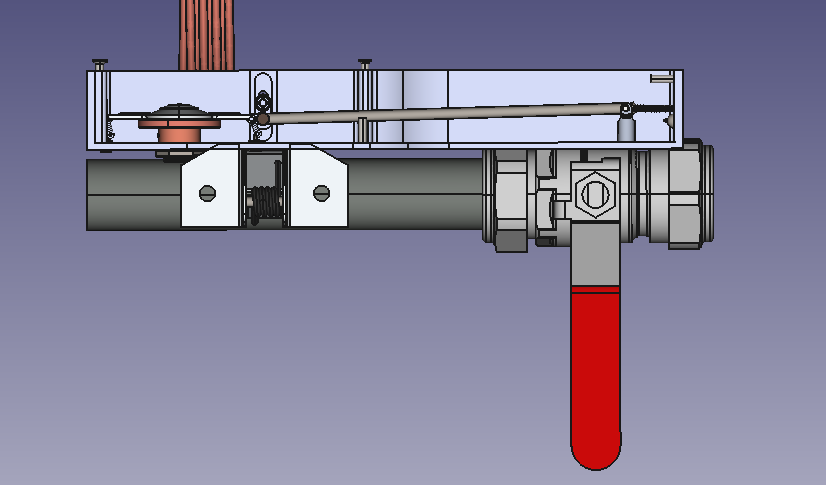

Temperature-Actuated Fluid Drain Valve Lockout Mechanism

The system operates using a sealed thermal bulb filled with a temperature-sensitive fluid. The bulb is positioned in the reservoir or piping system where it monitors fluid temperature. When the temperature exceeds 125°F, the fluid expands and transmits pressure through a capillary tube to a diaphragm.

As pressure builds, the diaphragm moves, transferring force to a spring-loaded mechanism that mechanically locks the valve handle. The valve remains secured until the fluid cools below 125°F. Once the fluid contracts, the diaphragm resets, releasing the lockout and restoring valve functionality.

Fully Mechanical, Power-Free Operation

This safety mechanism functions without electrical components. It requires no sensors, wiring, or external power. Its fully mechanical design ensures reliability in high-temperature and contamination-prone environments, eliminating electronic failure points.

Engineered for OEM Compatibility

The temperature-actuated lockout mounts directly onto drain or discharge piping and interfaces with standard 2-piece and 3-piece ball valves. The external actuation linkage engages the valve handle to create a mechanical interlock without modifying the valve. This configuration supports straightforward OEM integration and retrofit applications across a wide range of systems.

Custom Temperature Setpoints Available

While the standard lockout engages at 125°F (52°C), custom temperature setpoints are available to match application-specific requirements. Setpoints can be configured for higher or lower thresholds depending on process safety needs, fluid properties, or regulatory compliance.

Thermal-Based Safety Control for Liquid and Vapor Systems

In many applications, including heated water, oils, or industrial liquids, discharge at elevated temperatures poses safety risks such as burns, splashing, and vapor exposure. This device enforces a mechanical interlock based on a thermal threshold, preventing premature valve operation and reducing hazard potential.

Key Features

• Lockout engagement at 125°F (52°C) standard.

• Custom temperature setpoints available

• Integrated 368 Hydrastat capillary temperature sensor

• Thermal bulb and capillary-driven diaphragm actuation

• Spring-loaded mechanical locking system

• No electronics, sensors, or power requirements

• Compatible with standard ball valves and pipe systems

Application Scope

• Commercial foodservice equipment

• Hot water and heated oil systems

• Industrial fluid and vapor containment

• OEM process equipment safety controls

Contact Us for OEM Collaboration

The Temperature-Actuated Fluid Drain Valve Lockout is currently in the development stage and not yet available on the market. If you are designing equipment that handles hot liquids or vapors and require a passive, temperature-sensitive safety interlock, contact us to discuss OEM integration opportunities. We provide technical data and support for engineering evaluations. To explore technical details of the integrated sensor, visit the 368 Hydrastat product page.