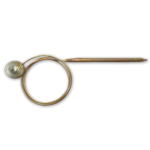

Immersion type controllers rely on capillary tube temperature sensors to regulate temperatures in water-based heating systems. These systems use liquid-filled capillary tubes, consisting of a sensing bulb, a flexible capillary tube, and a diaphragm. The bulb, immersed in the liquid medium (such as water), detects temperature changes and transmits mechanical signals through the capillary tube to the control mechanism. This process ensures reliable temperature management, whether for activating, deactivating, or protecting heating systems.

Immersion type controllers rely on capillary tube temperature sensors to regulate temperatures in water-based heating systems. These systems use liquid-filled capillary tubes, consisting of a sensing bulb, a flexible capillary tube, and a diaphragm. The bulb, immersed in the liquid medium (such as water), detects temperature changes and transmits mechanical signals through the capillary tube to the control mechanism. This process ensures reliable temperature management, whether for activating, deactivating, or protecting heating systems.

OEMs use these sensors in immersion type controllers to develop custom temperature control systems for residential, commercial, and industrial water heating applications.

Looking for dependable components for your immersion controllers? Contact us today to learn how our liquid-filled capillary tubes can support your designs. Visit our product page for more details.

Applications for Capillary Tube Temperature Sensors in Immersion Controllers

1. Boilers and Water Heaters

Immersion type controllers use capillary tube sensors to regulate water temperatures in boilers and water heating systems.

- How It Works: The sensing bulb, immersed in the water, monitors temperature and transmits signals to the control mechanism to activate or deactivate the heating element.

- Why Capillary Tubes Work: They provide steady, responsive temperature monitoring to maintain consistent water heating while preventing overheating.

2. Hydronic Heating Systems

Capillary tube temperature sensors control water temperatures in hydronic heating systems, such as radiant floor heating or baseboard heaters.

- How It Works: The bulb measures water temperatures in the hydronic loop and signals adjustments to the heating system to meet temperature requirements.

- Why Capillary Tubes Work: These assemblies allow precise temperature control, ensuring optimal performance and energy efficiency in water circulation systems.

3. Industrial and Commercial Heating Systems

Immersion controllers with capillary tubes are widely used in industrial and commercial water heating applications.

- How It Works: The bulb, immersed in the liquid medium, tracks temperature changes and sends signals to control heating elements for large-scale water tanks, process heaters, or hot water systems.

- Why Capillary Tubes Work: Their durable design ensures reliable performance in high-demand heating systems, even in extreme conditions.

How Capillary Tubes Work in Immersion Type Controllers

Capillary tube temperature sensors operate through liquid expansion and contraction. When the bulb detects an increase in temperature, the liquid inside expands, creating pressure that moves through the capillary tube to the diaphragm. This pressure activates the control mechanism to reduce or shut off heating. As the temperature decreases, the liquid contracts, prompting the control mechanism to increase heating output.

Capillary tube temperature sensors operate through liquid expansion and contraction. When the bulb detects an increase in temperature, the liquid inside expands, creating pressure that moves through the capillary tube to the diaphragm. This pressure activates the control mechanism to reduce or shut off heating. As the temperature decreases, the liquid contracts, prompting the control mechanism to increase heating output.

This mechanical operation makes capillary tube sensors a robust and straightforward solution for immersion controllers. They eliminate the need for complex electronics, ensuring consistent performance in water-based heating systems.

Why OEMs Use Capillary Tubes in Immersion Controllers

OEMs choose liquid-filled capillary tube assemblies for their immersion controllers because they:

- Enable Immersed Sensing: The sensing bulb provides direct temperature monitoring within water or other liquids.

- Allow Remote Placement: The capillary tube transmits temperature signals while keeping the control mechanism conveniently located for access.

- Offer Customization: Manufacturers can adjust capillary length, bulb size, and diaphragm sensitivity to suit specific system designs.

- Deliver Long-Term Durability: These assemblies perform reliably in demanding environments such as boilers, hydronic heating loops, and industrial water heaters.

Benefits for Immersion Type Controllers

OEMs integrate liquid-filled capillary tubes into immersion type controllers to:

- Maintain stable water temperatures in boilers, water heaters, and hydronic heating systems.

- Prevent overheating, ensuring safety and reducing energy waste.

- Deliver efficient and reliable temperature control for residential, commercial, and industrial applications.

- Create customizable and high-performance heating solutions tailored to specific systems.

By incorporating liquid-filled capillary tube assemblies, OEMs develop dependable immersion controllers for a wide range of heating applications.