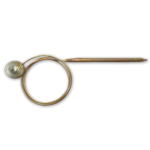

Remote bulb sensing for heating systems allows precise temperature monitoring and control in industrial applications. Liquid-filled capillary tube assemblies are commonly used in systems such as duct heaters, coil heaters, and industrial HVAC units. These assemblies consist of a liquid-filled bulb, a capillary tube, and a diaphragm. As the bulb detects temperature changes, the liquid expands or contracts, creating pressure that transmits through the tube to activate or deactivate the heating system.

Remote bulb sensing for heating systems allows precise temperature monitoring and control in industrial applications. Liquid-filled capillary tube assemblies are commonly used in systems such as duct heaters, coil heaters, and industrial HVAC units. These assemblies consist of a liquid-filled bulb, a capillary tube, and a diaphragm. As the bulb detects temperature changes, the liquid expands or contracts, creating pressure that transmits through the tube to activate or deactivate the heating system.

OEMs integrate these components into custom control systems to ensure reliable and consistent temperature regulation in moderate to high-temperature environments.

Looking for high-performance components for your heating systems? Contact us today to learn how our liquid-filled capillary tubes support remote bulb sensing for heating systems. Visit our product page for more details.

Applications for Remote Bulb Sensing in Heating Systems

Duct Heating Systems

Duct heaters rely on remote bulb sensing for accurate airflow temperature control.

- Air Temperature Control: The bulb, placed within the duct, senses the air temperature and adjusts the heating element to maintain consistent airflow.

- Overheating Prevention: If the air temperature exceeds a set limit, the sensor shuts off the heating element to protect the system.

OEMs integrate capillary assemblies into duct heating systems to provide reliable temperature sensing and remote monitoring.

Coil Heating Systems

Remote bulb sensing is used to regulate temperatures in industrial coil heaters.

- Coil Temperature Monitoring: The bulb, positioned near or wrapped around the heating coils, monitors their temperature and adjusts heat output as needed.

- Heat Stability: The sensor maintains consistent coil temperatures, preventing overheating and ensuring efficient operation.

Capillary assemblies offer precise control, making them ideal for managing heat levels in coil heating applications.

Space Heaters in Industrial HVAC Systems

Remote bulb sensing supports industrial HVAC systems by regulating zone temperatures across large spaces.

- Zone Temperature Control: The bulb monitors ambient temperatures in specific areas, sending signals to adjust heating levels.

- Energy Efficiency: The system reduces energy waste by maintaining steady temperatures without over-heating.

OEMs use these assemblies to build systems that deliver reliable heating in industrial environments.

How Remote Bulb Sensing Works in Heating Systems

Liquid-filled capillary tube assemblies respond to temperature changes through fluid expansion and contraction. When the bulb detects a temperature increase, the liquid expands, creating pressure that travels through the capillary tube to the diaphragm. This pressure activates the system to reduce heat or shut it off. Conversely, when temperatures drop, the liquid contracts, prompting the system to increase heating.

Liquid-filled capillary tube assemblies respond to temperature changes through fluid expansion and contraction. When the bulb detects a temperature increase, the liquid expands, creating pressure that travels through the capillary tube to the diaphragm. This pressure activates the system to reduce heat or shut it off. Conversely, when temperatures drop, the liquid contracts, prompting the system to increase heating.

This simple yet effective mechanical operation ensures consistent temperature control and eliminates the need for electronics, making these assemblies durable and dependable in industrial applications.

Why OEMs Use Remote Bulb Sensing for Heating Systems

OEMs rely on remote bulb sensing for heating systems to meet the demands of industrial applications. These assemblies offer:

- Remote Placement: The bulb can be positioned in ducts, near coils, or in hard-to-reach areas, while the control mechanism remains accessible.

- Customizable Options: Manufacturers can tailor capillary tube length, bulb size, and diaphragm sensitivity to meet specific system requirements.

- Smooth Operation: Liquid-filled designs expand and contract predictably, ensuring stable and consistent temperature control.

- High-Temperature Performance: These assemblies operate reliably in moderate to high-temperature environments.

Benefits for Industrial Heating Applications

OEMs designing industrial heaters integrate remote bulb sensing to:

- Maintain consistent airflow temperatures in duct heating systems.

- Stabilize heat levels in coil heating systems.

- Control ambient temperatures in HVAC zone heating systems.

- Create efficient, reliable, and energy-saving heating solutions for industrial environments.

By using liquid-filled capillary tube assemblies, OEMs deliver high-quality heating systems tailored to the needs of industrial applications.