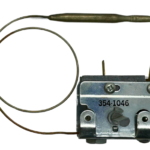

Capillary thermostats are widely used in heating, cooling, and temperature control systems. These devices use a capillary tube filled with a temperature-sensitive fluid to regulate temperature. Precise calibration of capillary thermostats is key for accurate performance. At our facility, we use salt and oil baths for calibration, leveraging their unique benefits. Here, we explain our process and the factors we consider. For additional questions regarding our calibration process, please do not hesitate to contact us.

Our Calibration Process with Salt and Oil Baths

Consistent Temperature Control

To achieve accurate calibration, we use salt and oil baths that provide a stable temperature environment. Their excellent heat transfer properties ensure uniform temperature throughout the process. By immersing the thermostat in a well-regulated salt or oil bath, we can establish a reliable reference temperature, minimizing any gradients that might lead to inaccuracies.

Wide Temperature Range

Capillary thermostats must operate across a broad range of temperatures, from sub-zero to high heat applications. Our salt and oil baths accommodate this wide range, allowing us to calibrate thermostats for various settings. We select different types of salts or oils based on the desired calibration temperature range, ensuring accuracy across different operating conditions.

Thermal Stability

Maintaining a constant temperature over an extended period is crucial for precise calibration. Our salt and oil baths provide this thermal stability, enabling us to observe the thermostat’s response accurately. This stability ensures reliable reference points for adjusting the thermostat’s setpoints, leading to precise calibration results.

Minimizing Environmental Interference

Calibrating capillary thermostats in ambient conditions can introduce environmental factors that affect accuracy, such as drafts and temperature fluctuations. By immersing the thermostat in a salt or oil bath, we create a controlled environment that shields it from such interferences. This allows us to focus solely on the calibration process, ensuring more precise results.

Safety Considerations

Safety is a priority in our calibration process. We use oil baths with high boiling point oils, such as silicone oil, which reduces the risk of evaporation and potential hazards from open flames or sparks. For high-temperature calibrations, we use salt baths with salts that have high melting points, providing a safe medium that can withstand extreme temperatures.

Choosing Between Salt and Oil Baths

Our choice between salt and oil baths depends on several factors:

Temperature Range

For lower temperature ranges (up to around 550°C or 1022°F), we use salt baths. For higher temperatures (up to approximately 300°C or 572°F), we opt for oil baths. This ensures that our calibration process matches the temperature range of the capillary thermostat.

Accuracy and Precision

We prioritize accuracy and precision in our calibrations. Salt baths offer better temperature uniformity and stability, resulting in higher accuracy, which is why we prefer them for more precise calibrations. Oil baths, while slightly less accurate, still meet the requirements for many applications.

Chemical Compatibility

The chemical compatibility of the capillary thermostat with the bath medium is also a crucial consideration. Salt baths use molten salts, which can react with or corrode certain materials. Oil baths offer better compatibility with a wider range of materials, so we ensure that the chosen bath medium does not damage or degrade the thermostat during calibration.

Safety and Environmental Factors

We evaluate safety considerations and environmental regulations. Salt baths operate at high temperatures and require proper safety measures for handling and disposal of molten salts. Oil baths, particularly those using non-toxic and non-flammable oils, pose fewer safety and environmental concerns.

At our facility, we carefully select between salt and oil baths for capillary thermostat calibration based on temperature range, accuracy, chemical compatibility, safety, and cost. This thorough assessment ensures our calibration process is reliable and precise, delivering optimal performance for our customers.