Understanding Capillary Thermostats

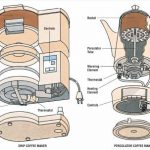

Capillary thermostats in food warming equipment consist of three essential components: a sensing bulb, a capillary tube, and a switch mechanism. The sensing bulb detects temperature via expansion or contraction of a fluid or bimetallic element. This thermal response is transmitted through the capillary tube, mechanically activating the switch to open or close the electrical circuit. Depending on the design, the thermostat functions as a control to regulate normal operating temperature or as a high-limit device to interrupt power in over-temperature conditions.

Capillary Thermostat Applications in Food Warming Equipment

Commercial Ovens and Ranges

Capillary thermostats in commercial ovens and ranges may operate as the primary control to manage set cooking temperatures or as high-limit cutoffs to prevent overheating. They ensure stable operation by activating heating elements or burners as needed, supporting safety and consistency in cooking performance.

Steam Tables and Bain Maries

In steam tables and bain maries, capillary thermostats are used to maintain desired water bath temperatures. They may act as adjustable controls to sustain holding temperatures or as fixed high-limits to shut down the system during fault conditions. This dual function helps maintain food safety and equipment protection.

Food Holding Cabinets

Food holding cabinets use capillary thermostats either to regulate the cabinet’s internal temperature or to serve as over-temperature protection. As controls, they maintain the proper thermal environment for ready-to-serve food. As high-limits, they safeguard against unsafe temperature excursions due to malfunction or component failure.

Hot Holding Drawers

In hot holding drawers, capillary thermostats help preserve food temperature and quality. They may serve as temperature controls for normal operation or as high-limit thermostats to disconnect power during overheating. This ensures compliance with safety standards and prevents product degradation.

Hot Food Boxes

In commercial hot food boxes, our bulb and capillary thermostats are used as the primary control to regulate internal temperature. Installed in the control panel, they manage power to the heating element by sensing cabinet conditions through fluid expansion. This enables consistent thermal performance during extended food holding periods, helping operators maintain ready-to-serve temperatures with dependable mechanical accuracy.

Heated Transport, Bulk Food, and Serving Carts

Our bulb and capillary thermostats are implemented as control mechanisms in heated transport carts, bulk food carts, and serving carts. These mechanical controls regulate the internal temperature by cycling power to the heating system based on fluid-responsive sensing. Positioned to maintain ideal thermal conditions during food transport or service, they help preserve product integrity from kitchen to destination. Their mechanical reliability ensures consistent performance even in high-vibration or mobile environments common to these cart-based applications.

Benefits of Capillary Thermostats in Food Warming Equipment

Capillary thermostats offer several advantages for industrial food warming equipment:

- Accuracy: They provide reliable temperature control, maintaining a consistent range to prevent undercooking or overheating.

- Versatility: Adjustable to different temperature ranges, they allow flexibility in food warming equipment.

- Durability: Capillary thermostats withstand the demanding conditions of industrial food environments, including high temperatures and humidity.

- Safety Features: Many include automatic shut-off and over-temperature protection, ensuring safe food temperatures and preventing accidents or foodborne illnesses.