A High limit capillary temperature switches can help control the circuits in your oven, especially if it is a commercial oven. In any oven, especially commercial ovens, there are two capillary thermostat control circuits. The first circuit controls the temperature in the heated chamber and the second is an OTP, or Over Temperature Protection circuit.

A High limit capillary temperature switches can help control the circuits in your oven, especially if it is a commercial oven. In any oven, especially commercial ovens, there are two capillary thermostat control circuits. The first circuit controls the temperature in the heated chamber and the second is an OTP, or Over Temperature Protection circuit.

For the purpose of our discussion we will use the word oven to denote any heated chamber used for cooking, curing, processing paint or adhesives, laboratory control and forming.

When your equipment is something more than a $20.00 pizza oven, and the value of the materials running through these heated chambers are more than a $10.00 pizza, it is of the utmost importance to have good over temperature protection. The OTP circuit is designed to shut down the heated chamber at a given temperature thus protecting the equipment and the product or process inside the oven. Continue reading below for more information!

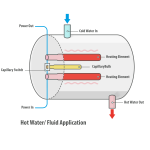

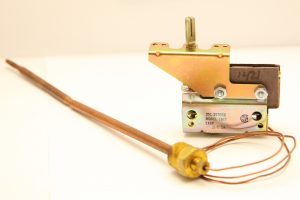

High Limit Capillary Temperature Switches have long been recognized as one of the best ways to protect your equipment and products in a heated chamber from temperature control failures and runaway heaters. Capillary thermostats work on basic physics, are reliable and operate even in a power outage. The basic theory is when a media such as gas or a fluid is heated it expands and when cooled contracts. That expansion or contraction trips a mechanical switch which opens or closes a circuit.

High temperature ovens up to approximately 900°F

In a higher temperature oven the bulb can be placed or attached to the outside of the inner chamber sensing the temperature of the outer wall. Considerations for wall thickness and heat transfer are important when designing maximum temperature of the capillary switch. How rapidly the temperature rises of falls will also be a consideration in this type of application.

In a higher temperature oven the bulb can be placed or attached to the outside of the inner chamber sensing the temperature of the outer wall. Considerations for wall thickness and heat transfer are important when designing maximum temperature of the capillary switch. How rapidly the temperature rises of falls will also be a consideration in this type of application.

Any device that requires a certification by UL, CSA, ECEE or any organization such as these will require an OTP circuit and if not it is always a good idea. There are differences between a low priced and a higher priced capillary switch. Penetration of the atmosphere into the switching portion is a big consideration. Construction testing and durability is another.

Let Senasys assist you with your next capillary thermostat design.